RESOURCES

Jamplast offers you specific details about our materials.

ENGINEERED PLASTICS

Thermoplastic Urethane ( TPU )

The different grades of TPU encompass a wide range of disparate characteristics. Polyester TPUs have better physical characteristics and oil resistance, while polyether TPUs have better hydrolytic stability. Reinforced TPUs find use in applications that require excellent dimensional stability like gears and agricultural parts.

Application: TPU applications include footwear, gears, rolls, wheels, belting, apparel, adhesives, sealants, laminating films, magnetic media binders, and medical tubing. New grades offer improved stability, food contact approval, non-halogen content for wire/cable, more elasticity, and film breathability.

Thermoplastic Elastomers ( TPE )

TPEs are a family of polymers that can be repeatedly stretched without permanently deforming the shape of the part. Unlike rubber-like elastomers, they do not require curing or vulcanization, as they are true thermoplastics. Thermoplastic elastomers (TPEs) may be processed by conventional thermoplastic techniques such as injection molding, extrusion and blow molding.

Application: Automotive, building and construction, soft touch grips and handles, caster treads and rollers.

Styrene Acrylonitrile ( SAN )

SAN is a material that has excellent chemical resistance, high flexural strength, good appearance and colorability, low impact, and it is processed very easily. Additionally, the transparency of SAN makes it one of the few plastics that can be used in clear applications.

Application: Housewares are a major market for SAN because of the resin’s glass-like clarity, excellent chemical resistance and good heat resistance. Typical applications include dishwasher-safe containers, disposable lighters, brush bristles, auto gauge covers, cosmetic cases, medical syringes, reflectors, refrigerator doors, and battery cases.

Polyphenylene Oxide ( PPO )

PPO is resin. Its high glass-transition temperature and high melt point give it heat resistance. Thematerial also has outstanding electrical properties and resistance to acids and bases.

Application: Modified PPO can be injection molded, blow molded, or extruded. Applications include automotive interior and exterior parts, business machines, medical equipment, telecommunications equipment, microwaveable packaging, appliances, and specialty uses.

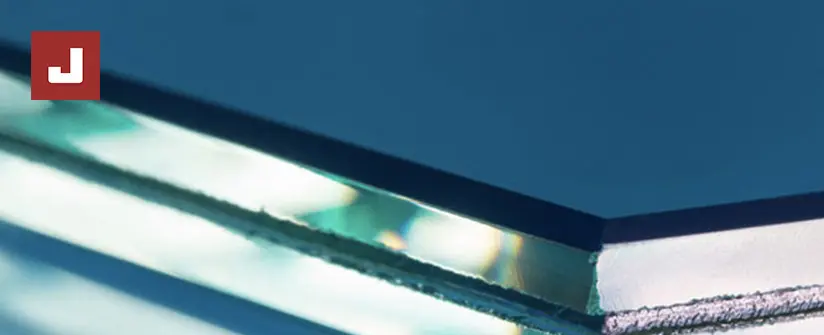

Polymethyl Methacrylate ( PMMA )

Polymethyl methacrylate is a transparent thermoplastic in the Acrylic family. It is clear weatherable plastic that resembles glass, but has properties that make it superior to glass in many ways.

Acrylic is used to make various products, such as shower doors, bath enclosures, windows and skylights. Acrylic insulates better than glass and weighs half as much. This makes working with acrylic much easier. It can also be sawed, whereas glass must be scored.

Application: shower doors, bath enclosures, windows and skylights, spice jars, small lens. Advantages: better insulator that glass, half as heavy as glass. It can be sawed and glass must be scored.

Polycarbonate Alloy/Polyethylene Terephthalate ( PC/PET )

PC/PET is a thermoplastic alloy that combines the excellent impact/toughness of polycarbonate with PET to create a unique set of properties for highly demanding applications.

Application: Widely used in automobile instrument panels, wheel covers, snowmobiles, and cellular phones. PET/PC alloys withstand the stresses created by jolting rides and the effects of extremes in temperature. PET/PC is an outstanding material for use in marine applications

Polycarbonate ( PC )

PC is characterized by excellent impact strength, glass-like transparency, and high dimensional stability. Additionally, PC has heat resistance, superb electrical properties, intrinsic flame-retardancy, low water absorption, and high dimensional accuracy out of the mold. Long-term exposure to humidity or water at high temperature is not advisable for PC.

Application: Most PC grades are for injection molding. Safety glazing, light covers, automotive headlamp lenses, water bottles, compact discs, and housings for electrical applications are produced from PC. Other applications include, power tool housings and large structural parts produced by foam molding, such as truck cabs, submarine battery jars, and gasoline pump or mainframe computer housings.

Polycarbonate Alloy/ABS ( PC / ABS )

PC/ABS is available in a range of engineering-grade blends that provide better mechanical performance than ABS and greater processing ease than PC. They have good aesthetics, being available in many colors and finishes, and are also paintable. PC/ABS alloys are used to make structurally strong parts for use in such market areas as appliances, automotive, building and construction, chemical processing, consumer goods, electronics, health care, and packaging.

Application: Widely used in automobile instrument panels, wheel covers, snowmobiles, and cellular phones, ABS/PC alloys withstand the stresses created by jolting rides and the effects of extremes in temperature. ABS/PC is especially known for its excellent low temperature properties.

Polybutylene Terephthalate ( PBT )

PBT is a semicrystalline engineering-grade thermoplastic that is part of the polyester family of resins. It resists moisture and a range of chemicals, and can achieve relatively high levels of izod impact strength through the use of impact modifiers.

Application: PBT can be used as an injection molded or blow molded material for high-quality, highly stressed engineering parts in a wide variety of industrial areas. Its high stiffness and strength combined with good heat aging performance and chemical resistance allows it to replace some metal parts in automotive applications.

Nylon

Nylon is one of the earliest-developed thermoplastic engineering resins in use worldwide. This material has outstanding properties, including high tensile strength and good resistance to creep, excellent abrasion, chemical, and heat resistance, and a low coefficient of friction.

Application: A large percentage of Nylon is compounded with glass fibers, mineral fillers and additives such as flame-retardants. The addition of fibers and fillers increases such properties as strength, stiffness, and decreasing moisture pickup. A large number of applications include automotive parts, roller skates, carpet, bike parts, kitchen items, sports equipment, and tool housings. Nylon can be processed through injection molding, extrusion, solution casting, roto-molding, blow molding and powder coating.

Acrylonitrile Styrene Acrylate ( ASA )

ASA is a two-phase thermoplastic material combining styrene-acrylonitrile copolymer and acrylic rubber. It has excellent weather resistance, so it is the best choice for outdoor applications.

Application: ASA can be injection molded, extruded as sheet or profiles and coextruded over ABS and PVC. ASA is used in outdoor applications that require long term color stability. Exterior siding, automotive side mirror housings, signage and marine applications are common uses for ASA.

Polyoxymethylene ( Acetal )

Acetal is a highly crystalline thermoplastic engineering resin that offers high mechanical properties and resists many chemicals. In particular, acetal is known for its high strength, creep resistance, resilience, surface hardness and lubricity, toughness, and excellent solvent and gasoline resistance. Additionally, it absorbs little water. There are two basic types of acetal resins: homopolymer and copolymer.

Application: Acetals can be injection molded, blow molded, and extruded as sheet and profiles. Regrind can be used, but is not recommended if optimum properties are needed. Acetals are used for molded and machined rollers, bearings, gears, conveyor chains, and housings. Furthermore, acetals are widely used in plumbing and irrigation because they resist scale buildup and have excellent thread strength. Automotive applications include, door handles, ventilation and cooling system parts, fuel system components, etc.

Acrylonitrile Butadiene Styrene ( ABS )

ABS Acrylonitrile-butadiene-styrene is the most widely used engineering thermoplastic today. The product has excellent surface appearance, strength, stiffness, toughness and chemical resistance—as well as its processing ease and versatility.

Application: ABS is often used for refrigerator door liners, interior automotive trim, coextruded sheets capped with a weatherable polymer, and housings for business machines, small appliances, telephones, and other consumer electronics. Furthermore, ABS offers a broad processing window with resins tailored for injection molding, profile extrusion, sheet extrusion and coextrusion, plating, rotomolding, compression molding, cold forming, and blow molding. ABS is easily machined, bonded, fastened, decorated, and finished.

COMMODITY GRADE PLASTICS

Polyvinyl Chloride ( PVC )

PVC is a versatile thermoplastic resins that can be formulated to be rigid or flexible. It has good chemical and heat resistance.

Application: flexible PVC is used in wire and cable jacketing, pool liners, flooring, garden hoses, rainwear and boots, and medical tubing.

Rigid PVC is used most commonly in building and constructions.

For exterior siding, windows, pipe fitting, sprinkler systems and office furniture edging.

Polypropylene ( PP )

PP’s ability to function as both a fiber and a thermoplastic allows it to be used in the manufacturing of many products in the durable and nondurable goods markets. The impact-resistant and cushioning properties of PP and its manufacturing versatility make it an ideal packaging material. Jamplast offers both homopolymer andcopolymer grades of PP.

Application: PP can be extruded, injected, or stretch-blow molded into containers and other hollow ware. The largest markets for commercial PP use are packaging, automotive, durables, consumer goods, and fibers. PP maintains its structural integrity while allowing the gamma rays to reach the food, which has enabled PP film to be used as a wrap for fresh foods and vegetables.

Polyolefin Elastomer ( POE )

POEs are flexible thermoplastics. This material is extrudable, moldable, and formable, and offers surprising benefits over conventional materials, such as flexible PVC, EVA, EMA, etc. POEs can provide excellent clarity, crack resistance, and weatherability. Furthermore, POEs deliver excellent processability without sacrificingphysical properties.

Application: impact modifier applications include interior trim

ducting, connectors and plugs, appliance parts, and garden furniture. Additionally, toys, grips, gaskets, and footwear can be produced

PET

PET resin belongs to the thermoplastic polyester class of plastics. These polyesters are used in textiles, packaging, industrial strapping, tire cord, and injection molding products. Currently, the fastest growing use is for food, beverage, and nonfood packaging applications.

Application: PET is used in synthetic fibers; beverage, food and other liquid containers; thermoforming applications; and engineering resins often in combination with glass fiber.

Polyethylene ( PE )

PE popularity is due to its ease of processing and relatively low cost. It is strong but lightweight, resistant to alkalis and acids, and can be used continually in temperatures up to 180 Fahrenheit. There are three basic types of PE resins: Low-density PE (LDPE), Linear low-density PE (LLDPE), and High-density PE (HDPE). HLMI HDPE has excellent stress cracking resistance, good impact and strength.

Application: PE can be processed through injection molding. It is used to create trash cans, dishpans, pails, and lids. Extrusion is used to process over half the PE sold in North America into film. Packaging film includes stretch and shrink wrap, grocery bags, laundry and dry cleaning bags. PE can also be used to make sheet, profile, pipe, and tubing. HLMI HDPE applications include barrels, dunnage trays, port-a-johns, and returnable pallets.

Medium Impact Polystyrenes ( MIPS )

Polystyrenes are highly versatile, relatively cheap materials that can be used in a wide range of applications. Extrusion and injection molding continue to be the predominant processing technologies for PS. They fall into three basic categories, general purpose (GPPS), high impact (HIPS) and medium impact (MIPS). All three categories are offered by Jamplast.

MIPS is a polymer product that has excellent gloss, high flow, good balance of toughness and easy processability.

Application: cassettes, housewares, closures, hangers, toys, and compact disc case inserts.

High Impact Polystyrenes ( HIPS )

Polystyrenes are highly versatile, relatively cheap materials that can be used in a wide range of applications. Extrusion and injection molding continue to be the predominant processing technologies for PS. They fall into three basic categories, general purpose (GPPS), high impact (HIPS) and medium impact (MIPS). All three categories are offered by Jamplast.

HIPS is specified for applications requiring more toughness than GPPS can provide.

Application: consumer durables, toys, electronics, housewares, flower pots and growing trays, and medical applications.

General Purpose Polystyrene ( GPPS )

Polystyrenes are highly versatile, relatively cheap materials that can be used in a wide range of applications. Extrusion and injection molding continue to be the predominant processing technologies for PS. They fall into three basic categories, general purpose (GPPS), high impact (HIPS) and medium impact (MIPS). All three categories are offered by Jamplast.

GPPS is a clear polymer that exhibits high stiffness, good dimensional stability, low specific gravity and excellent electrical properties. It offers several advantages over other polymers because of its clarity and ease of processing, both of which are due to its amorphous nature. GPPS has a relatively low cost and is forgiving when processed at high production rates.

Application: food packaging, refrigeration, audio/video, consumer electronics, office equipment, medical devices, and toys.

Ethylene Vinyl Acetate ( EVA )

EVA is a polymer that approaches elastomeric materials in softness and flexibility, yet can be processed like other thermoplastics. The material has good clarity and gloss, barrier properties, low-temperature toughness, and stress-crack resistance. EVA has little or no odor and is competitive with rubber and vinyl products in many electrical applications.

Application: adhesives, films consumer durables, blends with other thermoplastics, and medical.